- #Engineering stress vs true stress pdf cracked#

- #Engineering stress vs true stress pdf download#

- #Engineering stress vs true stress pdf crack#

Therefore, it is presumed that the lower limit of H V for fracture from Al 2O 3 The H-precharged specimen with H V=346 fractured by the cup-cone type. The H-precharged specimens with H V ≥447 fractured from Al 2O 3 The uncharged specimens with an H V of higher than H V = 447 fractured from TiN inclusions in five specimens, and from the specimen surface in one specimen, whereas the uncharged specimens with H V=346 fractured by cup-cone ductile shear failure. Tests on H-charged specimens were conducted at various hold times, 2, 24, 72 and 200 h in laboratory air after hydrogen charging. Table 22.3 summarises the results of tensile tests on SAE52100 specimens.

22.2, H-precharged specimens with an H V of higher than H V=447 fractured before yielding.

#Engineering stress vs true stress pdf crack#

#Engineering stress vs true stress pdf cracked#

This fact implies that TiN inclusions in the uncharged specimens were cracked under plastic deformation in a tensile test because TiN inclusions cannot follow large plastic deformation of the matrix. 22.3a and b), fracture origins are TiN inclusions. In both cases of uncharged specimens ( Fig. These inclusions are typical ones contained in ordinary commercial bearing steels such as SAE52100. Since Al and Ca were detected using EDX, the nonmetallic inclusions were identified to be Al 2O 3 22.3c and d shows a typical nonmetallic inclusion at a fracture origin of the H-precharged specimens. Since Ti and N were detected by EDX, the nonmetallic inclusions were identified to be TiN inclusions.

22.3a and b shows that the uncharged specimens also fractured from nonmetallic inclusions. Results for two levels of Vickers hardness, H V=678 and 559 are compared. The mating surfaces at the fracture origin are also shown in Fig. 22.3 compares the fracture surfaces of uncharged specimens and H-precharged specimens. Wayne Whiteman directly for information regarding the procedure to obtain a non-exclusive license.Fig. Any other use of the content and materials, including use by other academic universities or entities, is prohibited without express written permission of the Georgia Tech Research Corporation.

#Engineering stress vs true stress pdf download#

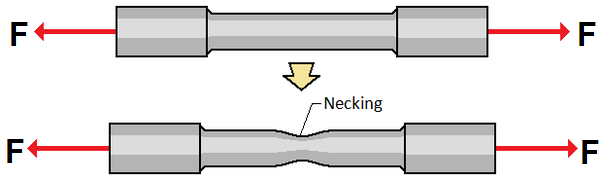

By participating in the course or using the content or materials, whether in whole or in part, you agree that you may download and use any content and/or material in this course for your own personal, non-commercial use only in a manner consistent with a student of any academic course. The copyright of all content and materials in this course are owned by either the Georgia Tech Research Corporation or Dr. Axial loading with be the focus in this course. The methods taught in the course are used to predict the response of engineering structures to various types of loading, and to analyze the vulnerability of these structures to various failure modes. This course explores the topic of solid objects subjected to stress and strain.

0 kommentar(er)

0 kommentar(er)